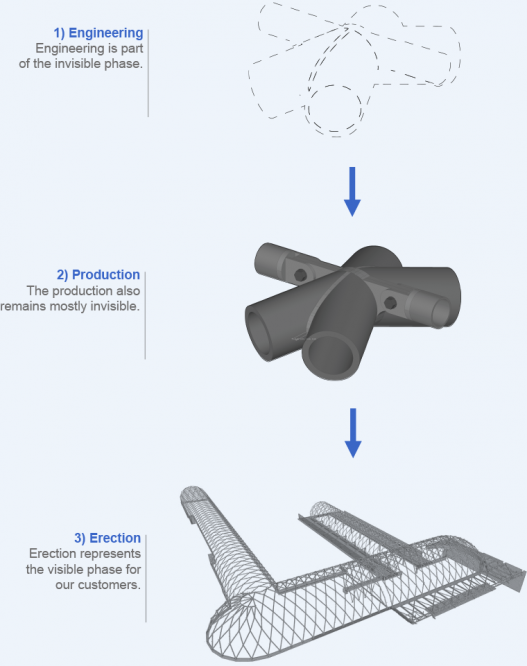

The digital twin – the DNA of your building

At Unger Steel Construction, your building is created as a 3D model containing all production-relevant data. It’s what we call a ‘digital twin’, which not only helps to visualise the building, but also serves as a reference for feedback processes and measurements.

This BIM model supports the entire construction process – from ordering of raw materials to production and fitting of the very last screw.

Three decades of experience in BIM planning

Unger Steel has been using BIM since 1989, although back then, its functionality was fairly limited. Since then, around 50 design engineers, 20 project managers, 5 structural engineers and 20 assembly foremen as well as the entire production management team have started to use Building Information Modelling.

– reduced steel:

– reduced steel: